Thomas A. Edison, a young inventor working in Menlo Park, New Jersey, began working on his own form of electric light in the 1870s. In 1877 Edison became involved with the rush for a satisfactory electric light source, devoting his initial involvement to confirming the reasons for his competitors’ failures. He did, however, determine that platinum made a much better burner than carbon. Working with platinum, Edison obtained his first patent in April of 1879 on a relatively impractical lamp, but he continued searching for an element that could be heated efficiently and economically.

Thomas A. Edison, a young inventor working in Menlo Park, New Jersey, began working on his own form of electric light in the 1870s. In 1877 Edison became involved with the rush for a satisfactory electric light source, devoting his initial involvement to confirming the reasons for his competitors’ failures. He did, however, determine that platinum made a much better burner than carbon. Working with platinum, Edison obtained his first patent in April of 1879 on a relatively impractical lamp, but he continued searching for an element that could be heated efficiently and economically.

Edison also tinkered with the other components of the lighting system, including building his own power source and devising a breakthrough wiring system that could handle a number of lamps burning at the same time. His most important discovery, however, was the invention of a suitable filament. This was a very thin, threadlike wire that offered high resistance to the passage of electric currents. Most of the early filaments burned out very quickly, thus rendering these lamps commercially useless. To solve this problem, Edison began again to try carbon as a means of illumination.

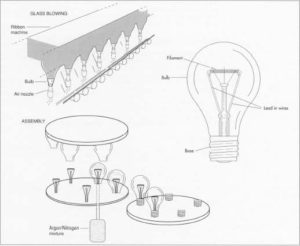

He finally selected carbonized cotton thread as his filament material. The filament was clamped to platinum wires that would carry current to and from the filament. This assembly was then placed in a glass bulb that was fused at the neck (called sealing-in). A vacuum pump removed the air from the bulb, a slow but crucial step. Lead-in wires that would be connected to the electrical current protruded from the glass bulb.

On October 19, 1879, Edison ran his first test of this new lamp. It ran for two days and 40 hours (October 21—the day the filament finally burned out—is the usual date given for the invention of the first commercially practical lamp). Of course, this original lamp underwent a number of revisions. Manufacturing plants were set up to mass produce light bulbs and great advances were made in wiring and electrical current systems. However, today’s incandescent light bulbs greatly resemble Edison’s original lamps. The major differences are the use of tungsten filaments, various gases for higher efficiency and increased lumination resulting from filaments heated to higher temperatures.

The Manufacturing Process

The uses of light bulbs range from street lights to automobile headlights to flashlights. For each use, the individual bulb differs in size and wattage, which determine the amount of light the bulb gives off (lumens). However, all incandescent light bulbs have the three basic parts—the filament, the bulb and the base. Originally produced by hand, the light bulb manufacture is now almost entirely automated.

Filament

- 1 The filament is manufactured through a process known as drawing, in which tungsten is mixed with a binder material and pulled through a die—a shaped orifice—into a fine wire. Next, the wire is wound around a metal bar called a mandrel in order to mold it into its proper coiled shape, and then it is heated in an process known as annealing. This process softens the wire and makes its structure more uniform. The mandrel is then dissolved in acid.

- 2 The coiled filament is attached to the lead-in wires. The lead-in wires have hooks at their ends which are either pressed over the end of the filament or, in larger bulbs, spot-welded.